INCOLLATRICE INCOLLATRICEINCOLLATRICE

INCOLLATRICEINCOLLATRICE

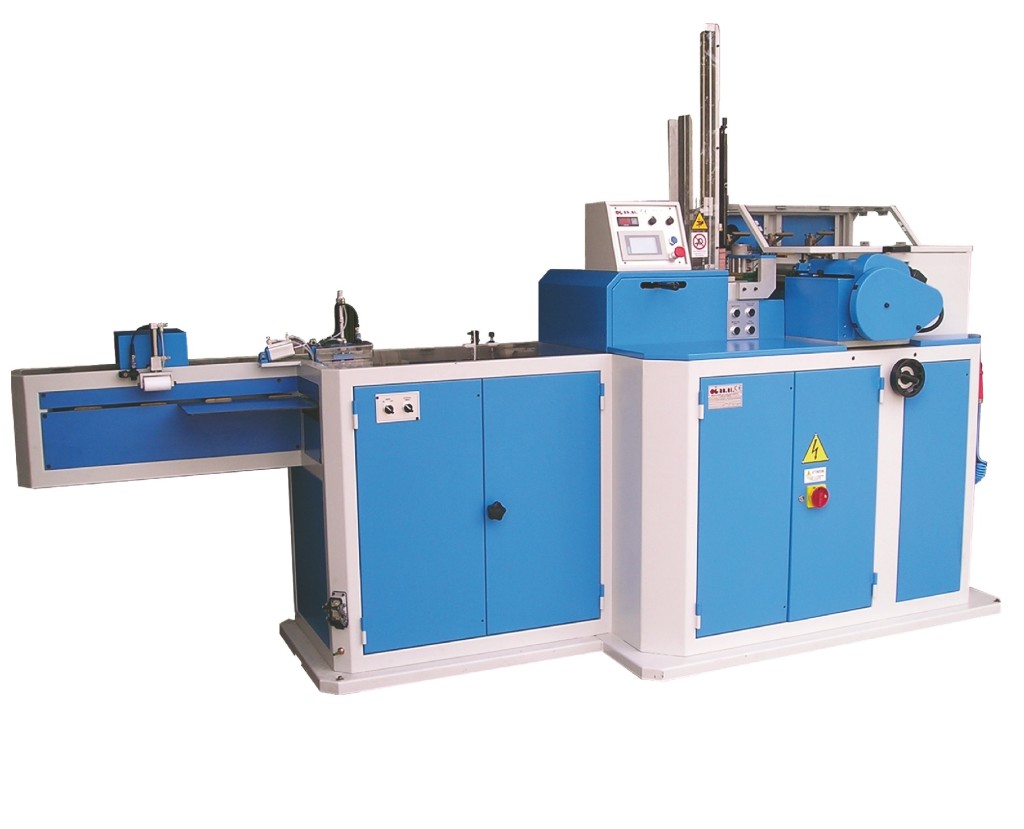

RG02IS – AUTOMATIC MACHINE FOR GLUING, STAMPING AND DRYING INSOLES

The machine allows the preparation of insoles needed to assemble footwear.

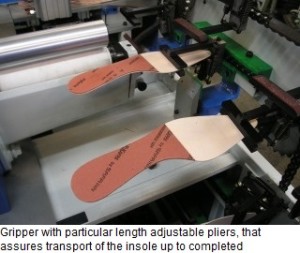

The insoles are manually picked from a container and stacked on a special column. From here, a pneumatic suction cup system sets them one at a time in the proper position to be picked up by the grippers. The grippers are mounted in series on a chain, are equipped with springs and are opened and closed by mechanical devices.

Once locked in the gripper, the insole starts along the path that takes it through the following processes:

- Passage through two rollers that distribute a layer of glue on the top;

- Several passages through the drying area with a heating system and two fans (this area is located in the internal part of the machine);

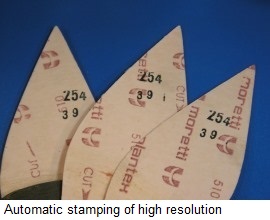

- Exit from the drying area and passage through the stamping area (the stamp may or may not be applied);

- Arrival at the ejection device that removes the insoles from the gripper and drops them in a container or Possibly on equipment that transports them elsewhere (conveyor belt or equivalent).

The gluing rollers and gripper-holder chains are moved by two distinct electric motors, while all of the oving organs (regulation of the width of the stack of insoles and right-left direction, stamper, stamp pad, ejection, etc.) are moved using pneumatic devices.